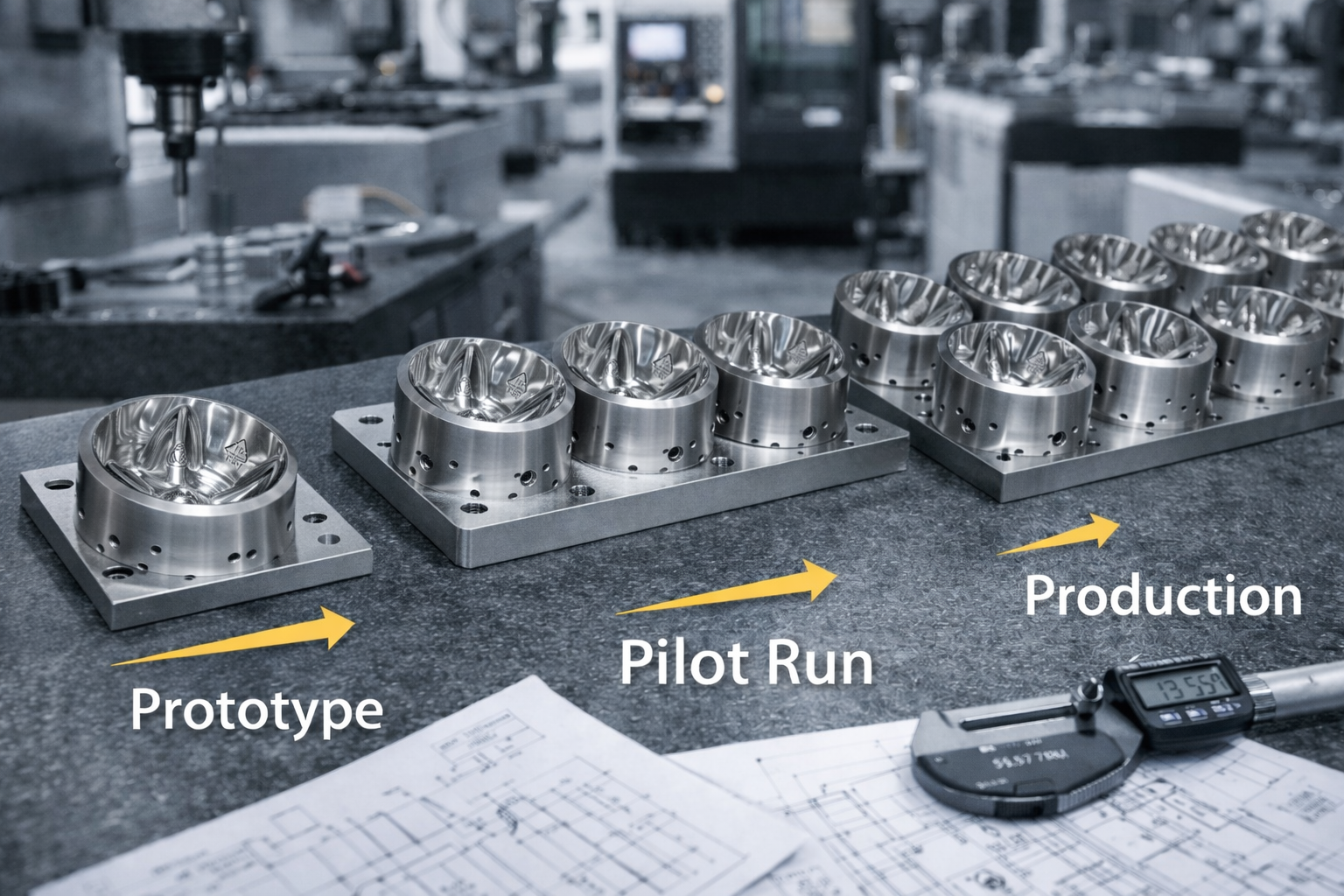

Prototype to Production CNC Machining: A Buyer’s Guide to Scaling Without Quality Problems

Many suppliers can make a prototype. Far fewer can take a part from prototype to production while keeping dimensions consistent, lead times stable, and costs predictable.

We are a CNC shop in Varna, Bulgaria with milling, turning, and 5-axis machining capabilities in aluminum, stainless steels, and tool steels, producing both prototypes and production parts (typical size up to ~400–600 mm).

Here we explain what changes when you scale—and what to ask us before you commit to production.

What’s different between a prototype and a production part?

A prototype often focuses on “does it work?”

Production focuses on:

-

repeatability across batches

-

stable setups and cycle times

-

predictable lead time

-

controlled inspection strategy

-

cost reduction without changing function

A shop that is good at production will invest in process, not just machining.

Step 1: Prototype phase—build the part and learn fast

In prototyping, speed matters.

The best CNC shops will:

-

run a quick DFM ( DFM = Design for Manufacturability) review (catch risks before cutting metal)

-

confirm critical-to-function dimensions

-

suggest changes that reduce cost or risk (radii, tolerances, tool access)

-

deliver a clean first article and feedback for revision

Prototype RFQ essentials

-

PDF + STEP

-

quantity (often 1–5 pcs)

-

material grade

-

what you’re testing (fit, strength, sealing, motion, heat)

Step 2: Pilot run—prove the process, not just the part

A pilot batch (e.g., 10–50 pcs) is where you validate:

-

fixture stability

-

tool wear behavior

-

cycle time repeatability

-

inspection method

-

yield (scrap rate)

What to ask for during a pilot run

-

identified critical dimensions and measurement method

-

a basic inspection report / first article verification

-

notes on process stability (what could vary and why)

This is where many projects fail—because the prototype worked, but the process was never proven.

Step 3: Production—reduce variation and control cost

In production, cost and consistency come from:

Standardized fixturing and setups

Repeatable soft jaws/fixtures reduce variation and operator dependence.

Tooling plan and wear control

Especially in stainless/tool steels, wear affects size and surface finish. Controlled tool changes + offsets keep parts consistent.

Locked process for critical features

Critical dimensions are measured in-process and at final inspection based on an agreed plan.

5-axis strategies to reduce setups

For parts with multiple faces and positional relationships, 5-axis machining can reduce re-clamping and improve consistency.

Managing engineering changes without chaos

Revisions happen. A good supplier will have a simple process:

-

clear revision control (which drawing version is being machined)

-

defined “stop and confirm” points for critical changes

-

documentation updates if inspection requirements change

If you expect changes, say so early—especially if you’re scaling fast.

RFQ checklist for scaling prototype to production

Send:

-

PDF drawing + STEP

-

quantity forecast (now + later)

-

material and finish

-

delivery target (dates)

-

critical dimensions / functional stack-ups

-

documentation needs (FAI, measurement reports)

A supplier can price better when they understand the roadmap (prototype → pilot → production).

Prototype to production CNC machining in Varna, Bulgaria

We provide:

-

CNC milling, turning, 5-axis machining

-

Materials: aluminum, stainless steels, tool steels

-

Prototype builds and repeat production

-

Typical part size up to ~400–600 mm

Request a quote: send your RFQ with PDF + STEP, quantities (now and later), material, finish, and target date. We’ll respond with a plan that supports both prototype speed and production repeatability.