Tight Tolerance CNC Machining: What’s Realistic, What It Costs, and How to Specify It (Without Overpaying)

When a drawing calls for tight tolerances, the real challenge isn’t “can you machine it?”—it’s can you machine it reliably, repeatedly, and prove it.

We’re a CNC machine shop in Varna, Bulgaria providing CNC milling, turning, and 5-axis machining in aluminum, stainless steels, and tool steels, from prototype to production, with typical part sizes up to ~400–600 mm.

Here we explain what tight tolerances mean in practice, what drives cost, and how to specify them so you get parts that fit and function—without paying for unnecessary precision.

What counts as “tight tolerance” in CNC machining?

“Tight” depends on the feature and the material. A tolerance that’s easy on one dimension may be difficult on another because of:

-

long tool reach and deflection

-

thin walls and vibration

-

heat growth in the part

-

multiple setups (stacking errors)

-

finishing/coating changes

Instead of thinking “tight everywhere,” think in terms of critical features:

-

bearing fits

-

sealing surfaces

-

true-position of holes

-

mating faces

-

concentricity/runout on turned parts

These are the dimensions where tight tolerances actually protect function.

The biggest cost drivers for tight tolerance parts

Tight tolerances usually increase cost because they require more of the following:

1) More setups and more rigid fixturing

Every time you re-clamp, you introduce potential variation. Complex parts may need custom fixtures, soft jaws, or 5-axis strategies to reduce setups.

2) Slower finishing passes

To hold size and finish, you often need light finishing cuts, stable tools, and conservative feeds.

3) Tool wear control

In stainless and tool steels especially, tool wear can move dimensions. Managing wear means more tool changes, offsets, and checks.

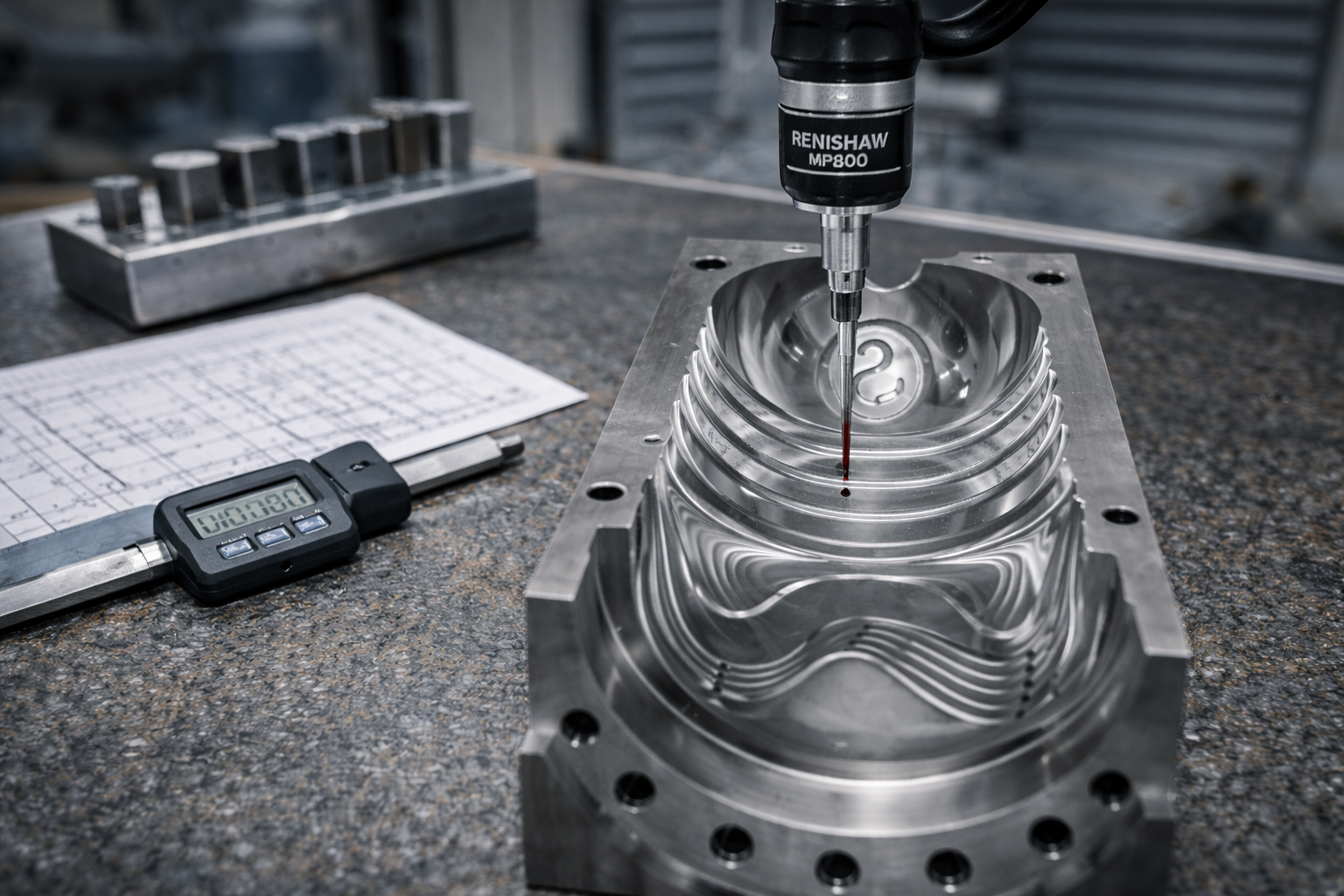

4) Higher inspection effort

Measuring can take as long as machining—especially for GD&T callouts, true position, or multi-feature reports.

5) Material behavior

-

Aluminum machines easily but can move if thin-walled.

-

Stainless can work harden and spring.

-

Tool steels may need heat treat—then dimensions can shift and require finish machining.

How to specify tight tolerances correctly (and avoid paying extra)

Use tight tolerances only on critical features

If a surface isn’t part of the functional stack-up, make it looser.

Define datums clearly

Good datums reduce interpretation and scrap. If the part must mate in a specific way, tell the shop which faces control the geometry.

Avoid “tight by default” notes

General notes like “ALL ±0.01” often create unnecessary cost. Better: apply tight callouts only where needed.

Choose GD&T (GD&T = Geometric Dimensioning and Tolerancing) that matches function

Overly strict GD&T can force extra setups and inspection without improving function. Use position/flatness/parallelism where it matters.

Consider 5-axis for multi-face accuracy

5-axis machining can reduce re-clamping, improving true-position relationships between faces and lowering risk.

Inspection: what you should request (and what you’ll receive)

For tight-tolerance parts, ask for:

-

first article check on prototypes or new revisions

-

measurement report on critical dimensions

-

specific checks for GD&T-critical features

A quality-focused CNC shop will agree on:

-

which dimensions are critical

-

how they will be measured

-

what documentation is included in the quote

RFQ checklist for tight tolerance CNC machining

To get an accurate quote fast, send:

-

PDF drawing with tolerances + GD&T

-

STEP model

-

quantity (prototype vs production)

-

material grade (aluminum / stainless / tool steel)

-

finish requirements

-

whether you need a measurement report / FAI

If there are critical fits (bearing/shaft/housing), include the mating part requirements or the functional intent.

Tight tolerance CNC machining in Varna, Bulgaria (our capabilities)

We support:

-

CNC milling, CNC turning, 5-axis machining

-

Materials: aluminum, stainless steels, tool steels

-

Prototype to production, including repeat batches

-

Typical part size up to ~400–600 mm, depending on geometry and setup

Request a quote: send your PDF + STEP + quantity + material and mark critical features. We’ll review manufacturability and respond with a clear lead time and inspection approach.